bioplasters

a study into bioplastics creation and application

methods: materials research, lab experiments, future scoping, laser cutting, market research, literature review

tags: biomaterials, health, food waste, product development

outputs: natural healing bandages made out of biomaterials, promotional video

tags: biomaterials, health, food waste, product development

outputs: natural healing bandages made out of biomaterials, promotional video

context: healing through natural materials, not wasteful single-use items

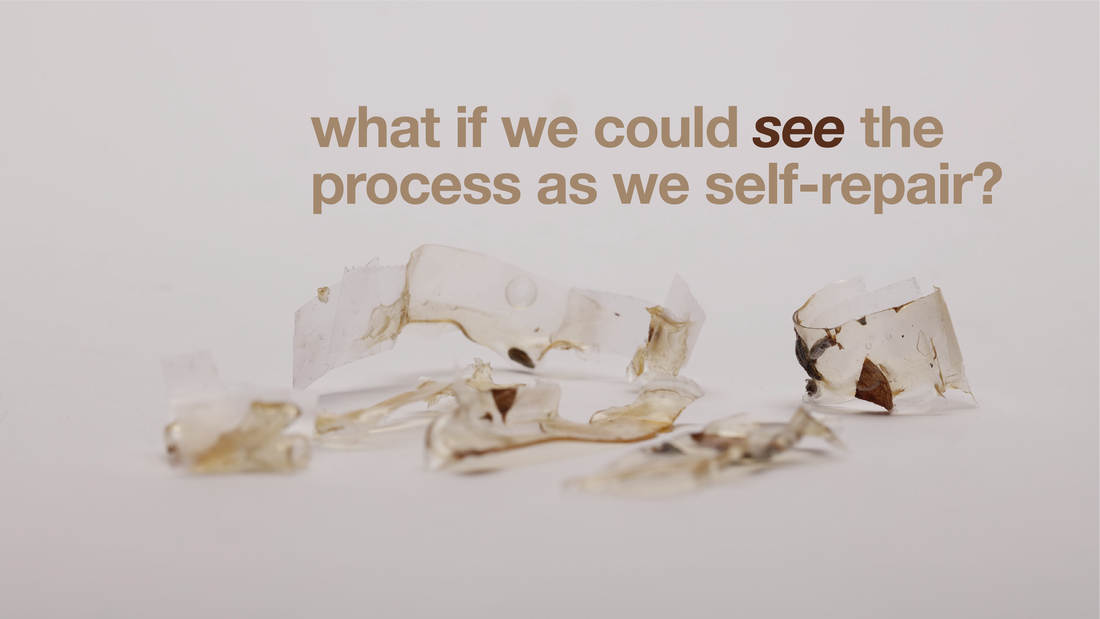

When we are injured, in order to repair and heal, we must protect the wounded area from infection. The primary consumer products we turn to are plasters (UK) or bandages (US), but they are wasteful, single-use items that contribute to plastic pollution on our planet. Can we mitigate this harmful behavior through the creation of biodegradable plasters that are still flexible and functional? I set out on an experimental journey through the realm of bioplastics to create bioplasters, which replace their landfill-bound counterparts with the added benefits of being transparent and fashionable. The aim is to see, feel, heal our injuries and our planet.

food waste is the negative space of our identity. can it be a material?

Waste is the negative space of our identity. What we discard can make a statement about us.

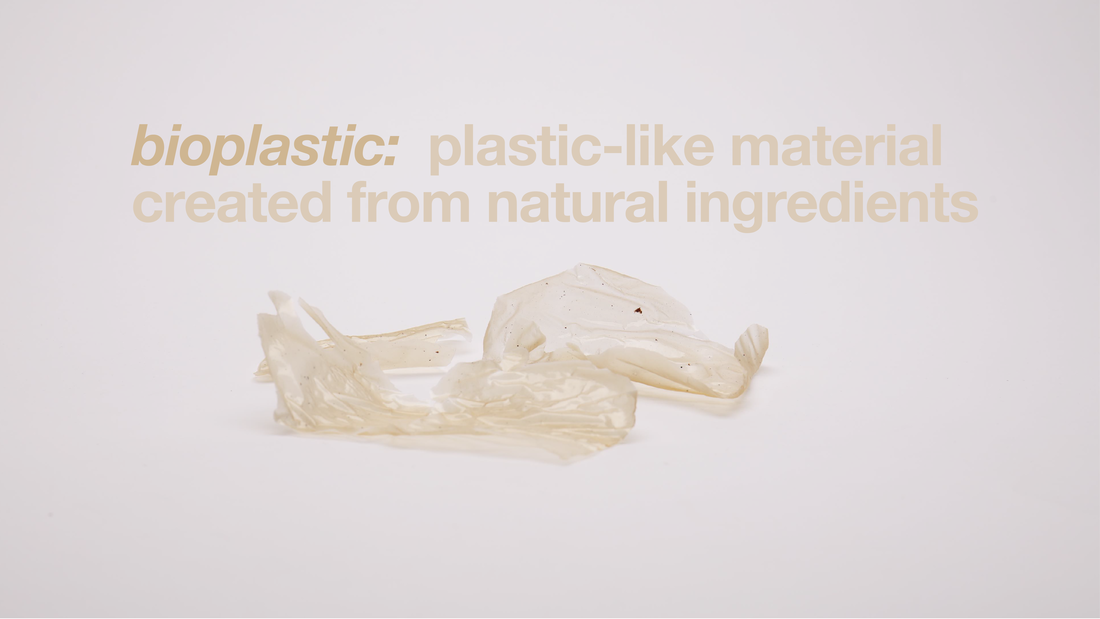

I wanted to experiment with using food waste as a material. As I was using the laser cutter, I heard that food could be cut on it. Inquiring further, I found that though they hadn’t cut any food on the laser before, some students had cut bioplastics. I decided to try doing both. It was simpler to actually make a bioplastic myself than to source it elsewhere. So I looked into a few recipes online, narrowed down to one, and got started with experimenting.

I wanted to experiment with using food waste as a material. As I was using the laser cutter, I heard that food could be cut on it. Inquiring further, I found that though they hadn’t cut any food on the laser before, some students had cut bioplastics. I decided to try doing both. It was simpler to actually make a bioplastic myself than to source it elsewhere. So I looked into a few recipes online, narrowed down to one, and got started with experimenting.

first experiments with creating bioplastics + laser cutting food & biomaterial

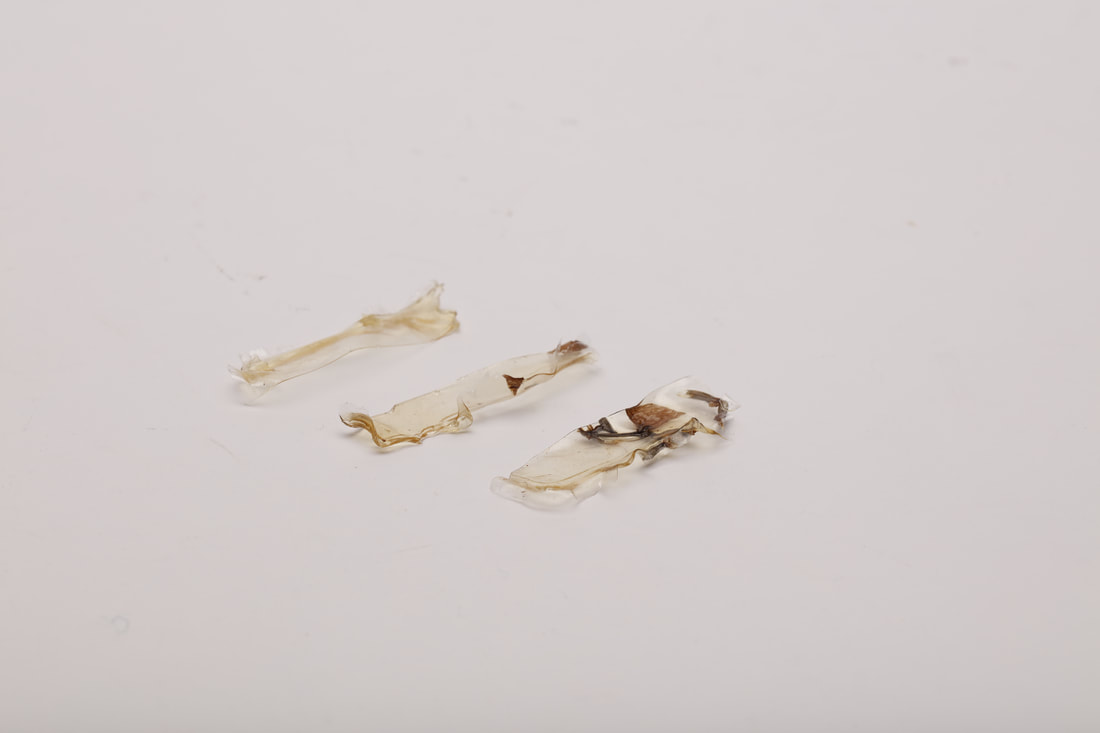

In my kitchen, I cooked up batches of glycerol + gelatin + hot water to create the bioplastics. I experimented with laser cutting and etching the bioplastics + food (dried apple slices and fruit rollup).

I also left the bioplastics in the open air to watch as they reacted to the environment: molding, curling, drying. I noticed thinner samples wouldn't form bacteria but would curl up more.

I also left the bioplastics in the open air to watch as they reacted to the environment: molding, curling, drying. I noticed thinner samples wouldn't form bacteria but would curl up more.

material exploration by adding food waste into bioplastics

I started experimenting with adding in food waste into the bioplastics, such as mixing clementine peel and using leftover pasta water. My hypothesis was that adding starch would strengthen the bioplastics... this was not true. They actually became soggier. I also tried again with rice water, which worked best when poured in a thin sheet... it actually resembled plastic packaging.

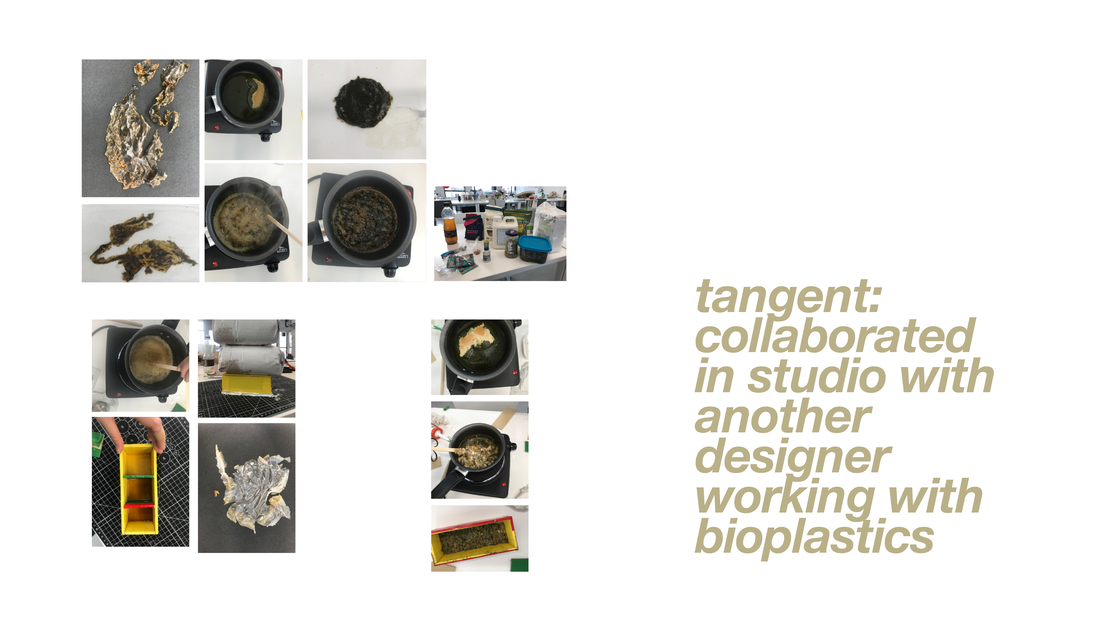

Another designer in studio was also working with biomaterial, and I took a pause in my project to collaborate with her. She had collected leaves from the ground and had wanted to try to make a more cement-like biomaterial; I brought in food waste and my own recipe to see what we could cook up together. It was an interesting side tangent!

turning the design & development cycle on its head

|

I approached this process a different way than usual. As a design practitioner and engineer, I’m used to the development cycle of a project where a problem is identified, a how might we statement is generated, insights are collected after research and ethnographic interviews, ideation happens, and a concept is iterated upon. In this project, I challenged my usual cycle to delve deep into the material first. This allows for a firmer understanding of the material before seeing where it can be applied, but as I am not a material scientist nor expert and when experiments fail, it can be easy to become lost.

I needed to reframe and go back to square one: market research and literature review to think about application. |

back to basics: market research & literature review to provide inspirationI looked into some existing use cases for biomaterials, such as in festivals as confetti or light sticks or in gardening as seed bombs. However, I was most intrigued by healing applications, such as by a durian-hydrogel bandage project at Nanyang Technological University. They only revamped the wound portion of the bandage but not the cover; I noticed that my microplastics would be sticky at point of first contact so I could possibly use them as an entire plaster / bandage.

|

a transparent, breathable, sustainable material for healing

With a focus on wound healing, I combined bioplastics + plasters to create bioplasters! It uses a thin form of the bioplastic gel, which creates a more transparent, breathable material for healing. Users can also add their own fashionable flair by cooking up their own recipes with discarded peels and petals.

I user tested a proof of concept for a day of wear.

I user tested a proof of concept for a day of wear.

preferable future: a new way of healingWhy stop at plasters? I've spoken to two contacts in the healthcare industry, a UK registered nurse and a US medical resident, who are excited by potential applications for splints, casts, and burn healing. Of course, this would need to go through more rigorous medical testing, but I see this as a potential avenue for further exploration.

Let's transform the way we heal. Let's make it transparent. |